Модель :

DW-325Тип :

Plunger PumpГладить :

4.5 Inches / 114.3 mmДиаметр цилиндра :

35-114mmПоток :

56.8-2346.7LPM/15-620GPMДавление :

6-58MPaПорт доставки :

Shanghai Port, ChinaГарантия :

12 MonthsТехнические характеристики:

| Стандарт дизайна | API-674, третье издание |

| Конфигурация | Горизонтальный пятипоршневой |

| Количество плунжеров | 5 |

| Непрерывная работа | 265 л.с. |

| Прерывистый режим работы | 325 л.с. |

| Длина хода | 4,5 дюйма / 114,3 мм |

| Номинальная нагрузка на раму | 12 500 фунтов / 5670 кг |

| Вес насоса (средний) | 4500 фунтов / 2041,2 кг |

| Номинальная скорость в прерывистом режиме | 400 об/мин |

| Номинальная скорость в непрерывном режиме | 330 об/мин |

| Минимальная скорость | 100 об/мин |

| Механическая эффективность | 90% |

| Система смазки | Всплеск, Гравитационный возврат |

| Объем масла в картере | 16 галлонов / 60,56 л |

| Тип смазочного масла | SAE30 |

| Диапазон температур жидкости | -20~350°F/-28~176°C |

| Тип клапана | Дисковый клапан / Износостойкий клапан |

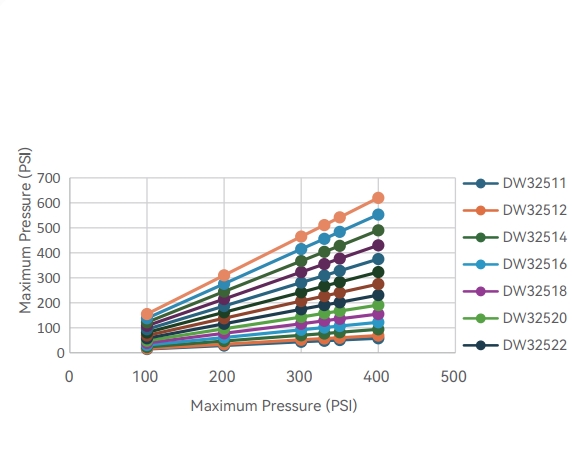

Данные о производительности (метрические):

| Модель насоса | Плунжер Диаметр (мм) | Смещение (Л/НАЗАД) | Максимум Давление (МПа) | Производительность насоса (л/мин) при входной скорости (об/мин) | |||||

| 100 | 200 | 300 | 350 | 400 | 425 | ||||

| DW32511 | 35 | 0,5473 | 58 | 56.8 | 109.8 | 166,5 | 181.7 | 193.0 | 219.5 |

| DW32512 | 38 | 0,6514 | 49 | 64.3 | 128.7 | 196.8 | 215.7 | 227.1 | 261.2 |

| DW32514 | 44 | 0,8868 | 36 | 87.1 | 177,9 | 265.0 | 291.4 | 310.4 | 355,8 |

| DW32516 | 51 | 1.1582 | 28 | 117.3 | 230.9 | 348.2 | 382.3 | 405.0 | 461.8 |

| DW32518 | 57 | 1.4659 | 21 | 147.6 | 295.2 | 439.1 | 484,5 | 514.8 | 586.7 |

| DW32520 | 64 | 1,8096 | 17 | 181.7 | 363.4 | 541.3 | 598.0 | 632.1 | 722.9 |

| DW32522 | 70 | 2.1896 | 14 | 219.5 | 439.1 | 658.6 | 722.9 | 764.6 | 874.3 |

| DW32524 | 76 | 2.6060 | 12 | 261.2 | 522.3 | 783.5 | 859.2 | 912.2 | 1040.9 |

| DW32526 | 83 | 3.0583 | 10 | 306.6 | 613.2 | 916.0 | 1010.6 | 1071.2 | 1222.6 |

| DW32528 | 89 | 3.5469 | 9 | 355,8 | 707.8 | 1063.6 | 1169.6 | 1241.5 | 1419.4 |

| DW32530 | 95 | 4.0719 | 8 | 408.8 | 813.8 | 1222.6 | 1343.7 | 1426.9 | 1627.6 |

| DW32532 | 102 | 4.6328 | 7 | 461.8 | 927.3 | 1389.1 | 1529.1 | 1620.0 | 1854.7 |

| DW32534 | 108 | 5.2301 | 6 | 522.3 | 1044.7 | 1570.8 | 1726.0 | 1831.9 | 2093.1 |

| DW32536 | 114 | 5.8633 | 6 | 586.7 | 1173.4 | 1760.0 | 1934.1 | 2051.5 | 2346.7 |

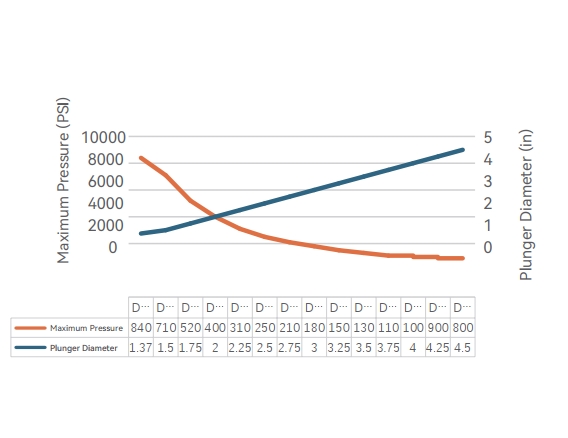

Производительность Данные:

| Насос Модель | Плунжер Диаметр (в) | Смещение (ГАЛ/ОБЗОР) | Максимум Давление (ФСИ) | Производительность насоса (галлоны в минуту) при входной скорости (об/мин) | |||||

| 100 | 200 | 300 | 350 | 400 | 425 | ||||

| DW32511 | 1.375 | 0,1446 | 8400 | 15 | 29 | 44 | 48 | 51 | 58 |

| DW32512 | 1.5 | 0,1721 | 7100 | 17 | 34 | 52 | 57 | 60 | 69 |

| DW32514 | 1.75 | 0,2343 | 5200 | 23 | 47 | 70 | 77 | 82 | 94 |

| DW32516 | 2 | 0,306 | 4000 | 31 | 61 | 92 | 101 | 107 | 122 |

| DW32518 | 2.25 | 0,3873 | 3100 | 39 | 78 | 116 | 128 | 136 | 155 |

| DW32520 | 2.5 | 0,4781 | 2500 | 48 | 96 | 143 | 158 | 167 | 191 |

| DW32522 | 2.75 | 0,5785 | 2100 | 58 | 116 | 174 | 191 | 202 | 231 |

| DW32524 | 3 | 0,6885 | 1800 | 69 | 138 | 207 | 227 | 241 | 275 |

| DW32526 | 3.25 | 0,808 | 1500 | 81 | 162 | 242 | 267 | 283 | 323 |

| DW32528 | 3.5 | 0,9371 | 1300 | 94 | 187 | 281 | 309 | 328 | 375 |

| DW32530 | 3.75 | 1.0758 | 1100 | 108 | 215 | 323 | 355 | 377 | 430 |

| DW32532 | 4 | 1.224 | 1000 | 122 | 245 | 367 | 404 | 428 | 490 |

| DW32534 | 4.25 | 1.3818 | 900 | 138 | 276 | 415 | 456 | 484 | 553 |

| DW32536 | 4.5 | 1.5491 | 800 | 155 | 310 | 465 | 511 | 542 | 620 |

Стандартные размеры соединений:

| Модель насоса | Всасывание (вход) | Разряд(в) |

| DW32511-DW32518 | 4.0 | 2.0 |

| DW32520-DW32528 | 6.0 | 3.0 |

| DW32530-DW32536 | 8.0 | 4.0 |

Материалы гидроцилиндра:

| Материалы гидроцилиндров | Бросать |

| Углеродистая сталь | Ковкий чугун |

| Высокопрочная углеродистая легированная сталь | Алюминиевая бронза |

| Нержавеющая сталь 304 / 316L / 17-4PH / 2205 / 2507 |

*Специальные материалы доступны по запросу.

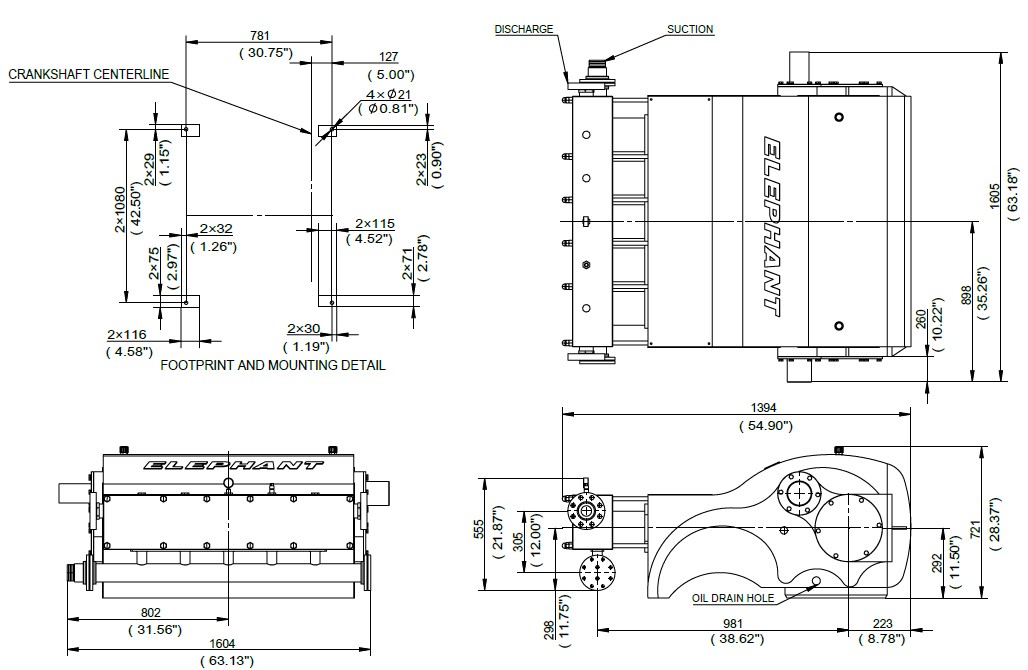

Инженерный размерный план

Часто задаваемые вопросы

1. Каков типичный срок службы насоса обратного осмоса?

Срок службы насоса обратного осмоса зависит от условий эксплуатации, качества воды и регулярного технического обслуживания. При правильном обслуживании и разумной эксплуатации срок службы обычно составляет от 5 до 10 лет, а некоторые высококачественные модели служат ещё дольше.

2. Как определить, нуждается ли насос обратного осмоса в замене или ремонте?

Такие признаки, как значительное снижение давления на выходе, уменьшение расхода воды, ненормальный шум при работе или утечка воды, могут указывать на неисправность или износ насоса. Необходимы срочный осмотр и последующий ремонт или замена.

3. Могут ли насосы обратного осмоса работать с водой высокой жесткости?

Да. Высококачественные насосы обратного осмоса обычно обладают коррозионной стойкостью и защитой от накипи, что позволяет им работать с водой высокой жёсткости. Тем не менее, рекомендуется регулярно очищать насос и систему, чтобы предотвратить образование накипи, которая может снизить производительность.

4. Какие меры предосторожности следует соблюдать при установке насоса обратного осмоса?

Убедитесь, что насос установлен горизонтально, чтобы предотвратить вибрацию и ослабление. Убедитесь, что все трубные соединения герметичны, а напряжение питания соответствует требованиям оборудования, чтобы гарантировать безопасную и стабильную работу.