Модель :

DS-142Тип :

Plunger PumpГладить :

4.0 Inches / 101.6 mmДиаметр цилиндра :

29-114mmПоток :

19.7-1328.5LPM/5.2-351GPMДавление :

4-69MPaПорт доставки :

Shanghai Port, ChinaГарантия :

12 MonthsТехнические характеристики:

| Стандарт дизайна | API-674, третье издание |

| Конфигурация | Горизонтальный трехплунжерный |

| Количество плунжеров | 3 |

| Непрерывная работа | 117 л.с. |

| Прерывистый режим работы | 142 л.с. |

| Длина хода | 4,0 дюйма / 101,6 мм |

| Номинальная нагрузка на раму | 9800 фунтов / 4445,28 кг |

| Вес насоса (средний) | 2400 фунтов / 1088,64 кг |

| Номинальная скорость в прерывистом режиме | 425 об/мин |

| Номинальная скорость в непрерывном режиме | 350 об/мин |

| Минимальная скорость | 100 об/мин |

| Механическая эффективность | 90% |

| Система смазки | Всплеск, Гравитационный возврат |

| Объем масла в картере | 9 галлонов / 34,07 л |

| Тип смазочного масла | SAE30 |

| Диапазон температур жидкости | -20~350°F/-28~176°C |

| Тип клапана | Дисковый клапан / Износостойкий клапан |

Данные о производительности (метрические):

| Модель насоса | Плунжер Диаметр (мм) | Смещение (Л/НАЗАД) | Максимум Давление (МПа) | Производительность насоса (л/мин) при входной скорости (об/мин) | |||||

| 100 | 200 | 300 | 350 | 400 | 425 | ||||

| DS14209 | 29 | 0,1953 | 69 | 19.7 | 39.0 | 58.7 | 68.5 | 78.0 | 82.9 |

| DS14210 | 32 | 0,2411 | 55 | 24.2 | 48.1 | 72.3 | 84.4 | 96,5 | 102.6 |

| DS14212 | 38 | 0,3475 | 38 | 34.8 | 69.6 | 104.1 | 121,5 | 138.9 | 147.6 |

| DS14214 | 44 | 0,4727 | 28 | 47.3 | 94.6 | 141.9 | 165.4 | 189.3 | 201.0 |

| DS14216 | 51 | 0,6177 | 21 | 61.7 | 123.4 | 185,5 | 216.1 | 247.2 | 262.7 |

| DS14218 | 57 | 0,7816 | 17 | 78.3 | 156.3 | 234.7 | 273.7 | 312.6 | 332.3 |

| DS14220 | 64 | 0,9652 | 14 | 96,5 | 193.0 | 289,6 | 338.0 | 386.1 | 408.8 |

| DS14222 | 70 | 1.1677 | 11 | 117.0 | 233,5 | 350,5 | 408.8 | 465.6 | 495,8 |

| DS14224 | 76 | 1.3899 | 9 | 138.9 | 277,8 | 416.4 | 484,5 | 556.4 | 590,5 |

| DS14226 | 83 | 1.6310 | 8 | 163.1 | 326.3 | 488.3 | 571.5 | 651.0 | 692.7 |

| DS14228 | 89 | 1,8917 | 7 | 189.3 | 378,5 | 567.8 | 662.4 | 757.0 | 802.4 |

| DS14230 | 95 | 2.1715 | 6 | 217.3 | 435.3 | 651 | 760,8 | 866.8 | 923.5 |

| DS14232 | 102 | 2.4708 | 5 | 247.2 | 495,8 | 741.9 | 863.0 | 987.9 | 1048.4 |

| DS14234 | 108 | 2.7892 | 4 | 279.0 | 556.4 | 836.5 | 976.5 | 1116.6 | 1184.7 |

| DS14236 | 114 | 3.1272 | 4 | 312.6 | 624.5 | 938.7 | 1093.9 | 1249.1 | 1328.5 |

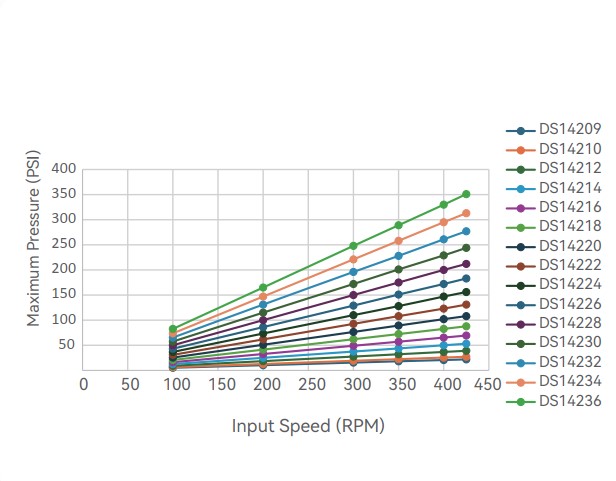

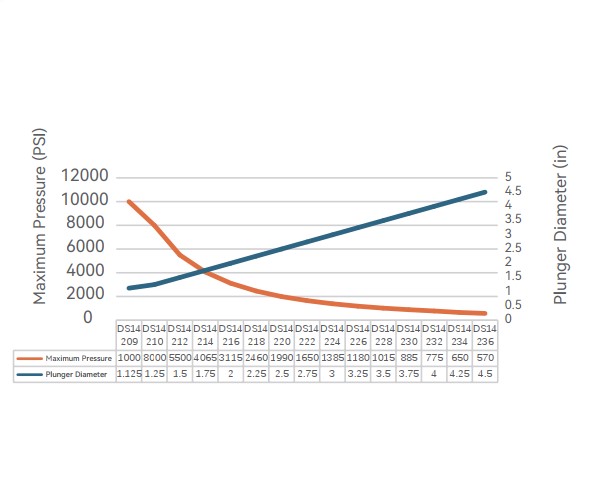

Производительность Данные:

| Насос Модель | Плунжер Диаметр (в) | Смещение (ГАЛ/ОБЗОР) | Максимум Давление (ФСИ) | Производительность насоса (галлоны в минуту) при входной скорости (об/мин) | |||||

| 100 | 200 | 300 | 350 | 400 | 425 | ||||

| DS14209 | 1.125 | 0,0516 | 10000 | 5.2 | 10.3 | 15.5 | 18.1 | 20.6 | 21.9 |

| DS14210 | 1.25 | 0,0637 | 8000 | 6.4 | 12.7 | 19.1 | 22.3 | 25.5 | 27.1 |

| DS14212 | 1.5 | 0,0918 | 5500 | 9.2 | 18.4 | 27.5 | 32.1 | 36.7 | 39 |

| DS14214 | 1.75 | 0,1249 | 4065 | 12.5 | 25 | 37,5 | 43.7 | 50 | 53.1 |

| DS14216 | 2 | 0,1632 | 3115 | 16.3 | 32.6 | 49 | 57.1 | 65.3 | 69.4 |

| DS14218 | 2.25 | 0,2065 | 2460 | 20.7 | 41.3 | 62 | 72.3 | 82.6 | 87.8 |

| DS14220 | 2.5 | 0,255 | 1990 | 25.5 | 51 | 76,5 | 89.3 | 102 | 108 |

| DS14222 | 2.75 | 0,3085 | 1650 | 30.9 | 61.7 | 92.6 | 108 | 123 | 131 |

| DS14224 | 3 | 0,3672 | 1385 | 36.7 | 73.4 | 110 | 128 | 147 | 156 |

| DS14226 | 3.25 | 0,4309 | 1180 | 43.1 | 86.2 | 129 | 151 | 172 | 183 |

| DS14228 | 3.5 | 0,4998 | 1015 | 50 | 100 | 150 | 175 | 200 | 212 |

| DS14230 | 3.75 | 0,5737 | 885 | 57.4 | 115 | 172 | 201 | 229 | 244 |

| DS14232 | 4 | 0,6528 | 775 | 65.3 | 131 | 196 | 228 | 261 | 277 |

| DS14234 | 4.25 | 0,7369 | 650 | 73.7 | 147 | 221 | 258 | 295 | 313 |

| DS14236 | 4.5 | 0,8262 | 570 | 82.6 | 165 | 248 | 289 | 330 | 351 |

Стандартные размеры соединений:

| Модель насоса | Всасывание (вход) | Разряд(в) |

| DS14209-DS14218 | 3.0 | 1.5 |

| DS14228-DS14236 | 4.0 | 2.0 |

| DS14228-DS14236 | 6 | 3 |

Материалы гидроцилиндра:

| Материалы гидроцилиндров | Бросать |

| Углеродистая сталь | Ковкий чугун |

| Высокопрочная углеродистая легированная сталь | Алюминиевая бронза |

| Нержавеющая сталь 304 / 316L / 17-4PH / 2205 / 2507 |

*Специальные материалы доступны по запросу.

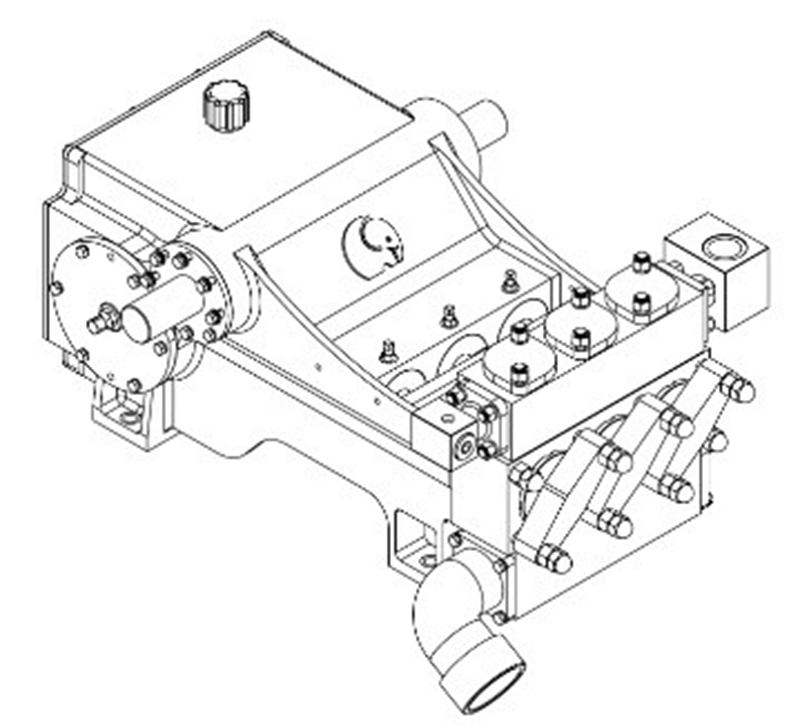

Функции

The поршневой насос для впрыска химикатов предлагает универсальную функциональность в сочетании с высокой степенью адаптивности и надежности в промышленных приложениях, предоставляя эффективные решения для сложных технологических процессов.

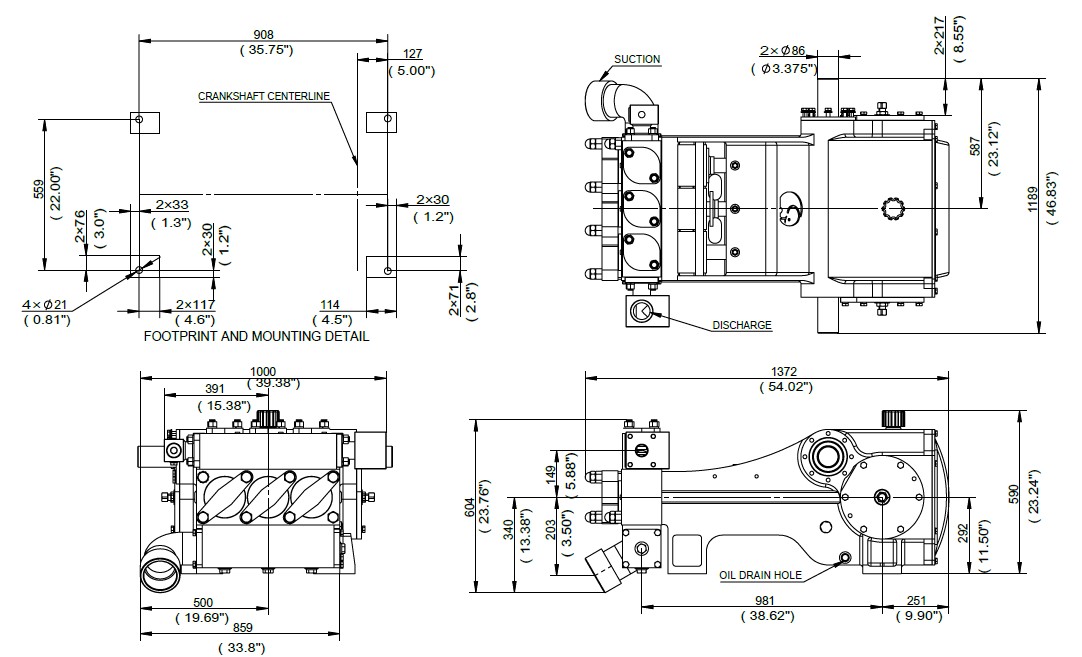

Инженерный размерный план

Преимущества

Заключение

Машины-слоны поршневые насосы Разработаны и изготовлены в строгом соответствии с китайскими национальными стандартами, такими как GB/T-9234, а также международными авторитетными стандартами, включая API 674 (третье издание) и ISO 13710, что гарантирует ведущие в отрасли показатели производительности по всем показателям. Поршневые насосы Elephant Machinery отличаются исключительной адаптивностью и надежностью, отвечая строгим требованиям к высокоточной подаче потока и стабильному выходному давлению в различных областях применения, включая нефть и газ, химическая обработка, производство электроэнергии, и очистка воды. Они предоставляют клиентам эффективные и долговечные решения в области электроснабжения.