Модель :

DS-77Тип :

Plunger PumpГладить :

3.0 Inches / 76.2 mmДиаметр цилиндра :

22-76mmПоток :

8.7-522.3LPM/2.3-138GPMДавление :

6-69MPaПорт доставки :

Shanghai Port, ChinaГарантия :

12 MonthsТехнические характеристики:

| Стандарт дизайна | API-674, третье издание |

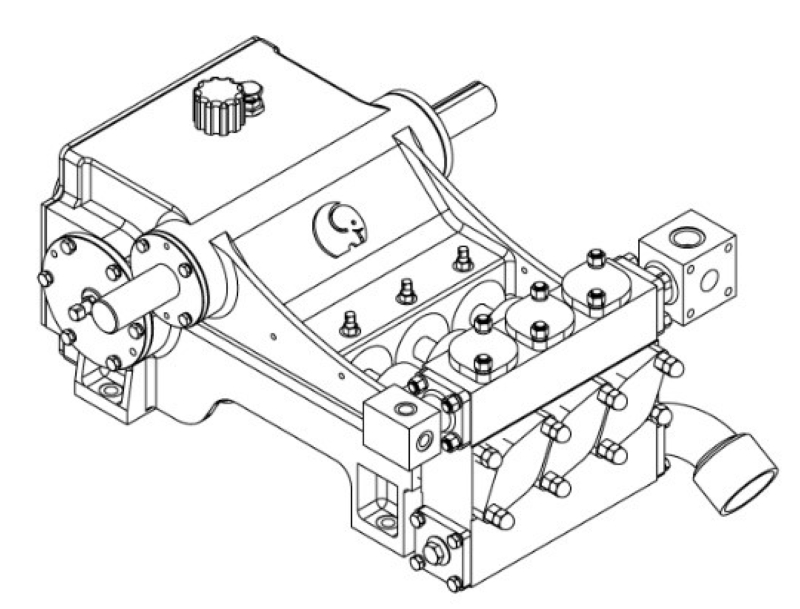

| Конфигурация | Горизонтальный трехплунжерный |

| Количество плунжеров | 3 |

| Непрерывная работа | 62 л.с. |

| Прерывистый режим работы | 77 л.с. |

| Длина хода | 3,0 дюйма / 76,2 мм |

| Номинальная нагрузка на раму | 6000 фунтов / 2721,6 кг |

| Вес насоса (средний) | 950 фунтов / 430,92 кг |

| Номинальная скорость в прерывистом режиме | 500 об/мин |

| Номинальная скорость в непрерывном режиме | 400 об/мин |

| Минимальная скорость | 100 об/мин |

| Механическая эффективность | 90% |

| Система смазки | Всплеск, Гравитационный возврат |

| Система смазки (опционально) | 3,25 галлона / 12,0 л |

| Тип смазочного масла | SAE30 |

| Диапазон температур жидкости | -20~350°F/-28~176°C |

| Тип клапана | Дисковый клапан / Износостойкий клапан |

Данные о производительности (метрические):

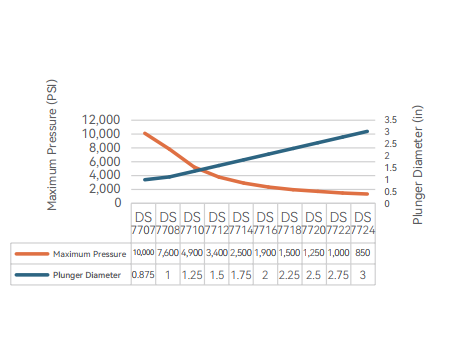

| Насос Модель | Плунжер Диаметр (мм) | Смещение (Л/НАЗАД) | Максимум Давление (МПа) | Производительность насоса (л/мин) при входной скорости (об/мин) | ||||||

| 100 | 200 | 300 | 350 | 400 | 450 | 500 | ||||

| DS7707 | 22 | 0,0886 | 69 | 8.7 | 17.8 | 26.5 | 31.0 | 35.6 | 39.7 | 44.3 |

| DS7708 | 25 | 0,1158 | 52 | 11.7 | 23.1 | 34.8 | 40,5 | 46.2 | 52.2 | 57.9 |

| DS7710 | 32 | 0,1809 | 34 | 18.2 | 36.3 | 54.1 | 63.2 | 72.3 | 81.4 | 90,5 |

| DS7712 | 38 | 0,2604 | 23 | 26.1 | 52.2 | 78 | 91.2 | 104.1 | 117.3 | 130.2 |

| DS7714 | 44 | 0,3547 | 17 | 35.6 | 70,8 | 106.4 | 124.1 | 141.9 | 159.7 | 177,5 |

| DS7716 | 51 | 0,4633 | 13 | 46.2 | 92.7 | 138.9 | 162 | 185,5 | 208.6 | 231.6 |

| DS7718 | 57 | 0,5863 | 10 | 58.7 | 117.3 | 176.0 | 205.1 | 234.7 | 263,8 | 293.3 |

| DS7720 | 64 | 0,7237 | 9 | 72.3 | 144.6 | 217.3 | 253.2 | 289,6 | 325,5 | 361.8 |

| DS7722 | 70 | 0,8758 | 7 | 87.4 | 175.2 | 262.7 | 306.6 | 350,5 | 393.6 | 439.1 |

| DS7724 | 76 | 1.0424 | 6 | 104.1 | 208.6 | 312.6 | 364.9 | 416.4 | 469.3 | 522.3 |

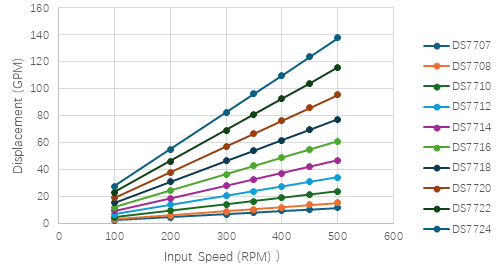

Производительность Данные:

| Насос Модель | Плунжер Диаметр (в) | Смещение (ГАЛ/ОБЗОР) | Максимум Давление (ФСИ) | Производительность насоса (галлоны в минуту) при входной скорости (об/мин) | ||||||

| 100 | 200 | 300 | 350 | 400 | 450 | 500 | ||||

| DS7707 | 0,875 | 0,0234 | 10,000 | 2.3 | 4.7 | 7 | 8.2 | 9.4 | 10.5 | 11.7 |

| DS7708 | 1 | 0,0306 | 7,600 | 3.1 | 6.1 | 9.2 | 10.7 | 12.2 | 13.8 | 15.3 |

| DS7710 | 1.25 | 0,0478 | 4,900 | 4.8 | 9.6 | 14.3 | 16.7 | 19.1 | 21.5 | 23.9 |

| DS7712 | 1.5 | 0,0688 | 3,400 | 6.9 | 13.8 | 20.6 | 24.1 | 27.5 | 31 | 34.4 |

| DS7714 | 1.75 | 0,0937 | 2500 | 9.4 | 18.7 | 28.1 | 32.8 | 37,5 | 42.2 | 46.9 |

| DS7716 | 2 | 0,1224 | 1900 | 12.2 | 24.5 | 36.7 | 42.8 | 49 | 55.1 | 61.2 |

| DS7718 | 2.25 | 0,1549 | 1500 | 15.5 | 31 | 46.5 | 54.2 | 62 | 69.7 | 77,5 |

| DS7720 | 2.5 | 0,1912 | 1,250 | 19.1 | 38.2 | 57.4 | 66.9 | 76,5 | 86 | 95.6 |

| DS7722 | 2.75 | 0,2314 | 1000 | 23.1 | 46.3 | 69.4 | 81 | 92.6 | 104 | 116 |

| DS7724 | 3 | 0,2754 | 850 | 27.5 | 55.1 | 82.6 | 96.4 | 110 | 124 | 138 |

Стандартные размеры соединений:

| Модель насоса | Всасывание (вход) | Разряд (в) |

| DS7707-DS7711 | 2.0 | 1.0 |

| DS7709-DS7716 | 3.0 | 1.5 |

| DS7712-DS7726 | 3.0 | 2.0 |

Материалы гидроцилиндра:

| Материалы гидроцилиндров | Бросать |

| Углеродистая сталь | Ковкий чугун |

| Высокопрочная углеродистая легированная сталь | Алюминиевая бронза |

| Нержавеющая сталь 304 / 316L / 17-4PH / 2205 / 2507 | |

*Специальные материалы доступны по запросу.

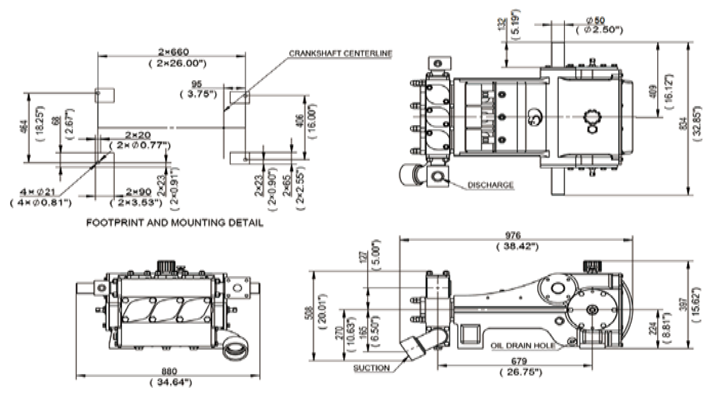

Инженерный размерный план

Преимущества

Химические насосы для закачки реагентов демонстрируют множество существенных преимуществ в практическом применении. Во-первых, их высокоэффективный режим работы существенно повышает производительность производства, одновременно снижая энергопотребление, что обеспечивает значительную экономическую выгоду для пользователей. Во-вторых, эти насосы обладают исключительной адаптивностью, сохраняя стабильную производительность в экстремальных температурных условиях или при работе с высоковязкими средами. Кроме того, их модульная конструкция облегчает модернизацию оборудования и расширение функционала, удовлетворяя потребность различных отраслей в индивидуальных решениях.

Ещё одно ключевое преимущество заключается в их передовых интеллектуальных возможностях. Современные насосы для закачки химических веществ, как правило, оснащены сложными системами управления, обеспечивающими удалённый мониторинг и автоматическую работу, что снижает частоту ручного вмешательства и связанные с ним эксплуатационные риски. Кроме того, возможности сбора и анализа данных в режиме реального времени предоставляют надёжную информацию для оптимизации производственных процессов и разработки графиков технического обслуживания. В совокупности эти характеристики составляют основное конкурентное преимущество насосов для закачки химических веществ в промышленном применении.

Основная функция